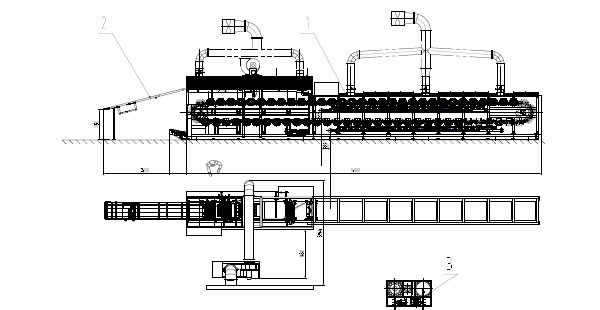

Boat Wafer Production Line: Production Flow

Batter Mixing – Batter Feeding – Baking – Discharging – Cooling

1. Batter mixing: Water, flour, edible oil and other ingredients should be prepared with a rational proportion, and then they are agitated in the wafer batter mixer for 3-5 minutes to form wafer batter for future use.

2. Batter feeding: A batter feeding unit delivers wafer batter to the mould cavity uniformly and intermittently, and it is mainly composed of three parts which are photoelectric wheel, rotor pump and feeding pipe.

3. Baking: Owing to the implementation of PLC, our baking oven could heat up baking plates to a desire temperature for better quality control.

4. Discharging: Wafer biscuits are discharged from baking plates, just like by a vacuum cleaner.

5. Cooling: Boat wafer biscuits are cooled naturally and deliver to other wafer processing equipment.