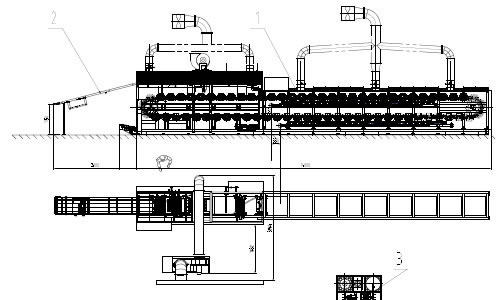

The 69-mould boat wafer production line, developed by ourselves in 2013, is an innovative product, and it has acquired one self-owned national patent. This wafer biscuit production line is mainly designed to make boat-shaped wafer biscuits, and its production capacity is about 33120 pieces per hour.

| 1 | Mould No. | 69 |

| 2 | Upper mould size (mm) | 470×350×32 |

| 3 | Lower mould size (mm) | 470×350×35 |

| 4 | Production capacity (pcs/min) | 24×23=552 |

| 5 | LNG consumption in m3/h (combustion value: 40337kJ/m3) | 50 |

| 6 | LPG consumption in m3/h (combustion value: 117462kJ/m3) | 20 |

| 7 | Compressed air consumption (m3/min) | 2 |

| 8 | Overall dimensions in mm (without exhaust pipe) | 14000×1820×2390 |

| 9 | Total weight (t) | 20 |

| 10 | Working direction | Right |

Related Names

Wafer Biscuit Production Line | Boat-Shaped Wafer Production Equipment | Food Machinery | Stainless Steel Batter Mixer | Stainless Steel Conveyor

System Configuration

1. Wafer Batter Mixer

2. KHG-69 Boat Wafer Baking Oven

3. Chain Conveyor